I’ve been picking away at the engine. The cylinder head has gotten a clean bill-of-health after inspection, pressure testing, and a shave. The SU carburetors are cleaned up, though not quite ready since replacement parts are needed. Bores are all measured, and they have little wear from the last rebuild, when .030-upsized pistons were installed. I have debated whether I should just go ahead and have new sleeves fitted and go back to the nominal bore of 3.4252″. Since the current bores are still in good shape, I think I’ll wait to do the more thorough rebuild. I’ll fit new rings on the old pistons.

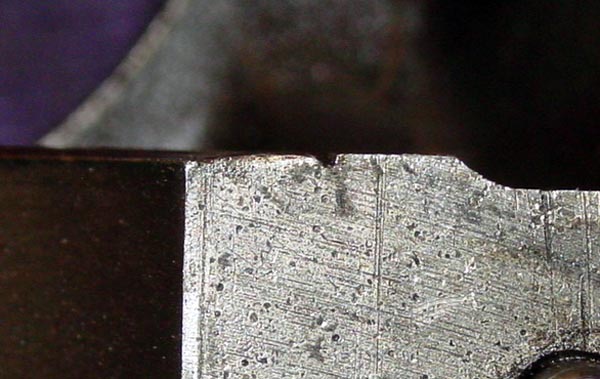

But there are still issues that trouble this engine work. Back when Aaron and I took the engine apart, we discovered the thrust washers unseated, with one of them sloshing around the oil pan. Their absence took its toll on the crankshaft and a part of the engine block. Pictures below tell the story. The crankshaft might be repairable, assuming that a good submerged weld could build up the face where the thrust washer fits. A ring-like ridge stands up about 0.045″ from the face where the thrust washer fits. I believe that entire depression would need building up. The ridge itself bit into the engine block in the absence of the thrust washer, and the are where the crankshaft met the block has been beveled slightly. That area would also need squaring up.

Obviously, the question in my mind now is whether the crankshaft is salvagable — or, for that matter, the block.