New engine! —New, at least for me

Very exciting! I picked up an engine to resolve the issues of the thrust washers and crankshaft. This one is a 4.2 liter XK from a 1979 model year XJ6. I used the free advertisement section of Jag Lovers to track it down. David Boger lives a little over two  hours down interstate 85 from me, and so it was an easy pickup after we made the deal.

hours down interstate 85 from me, and so it was an easy pickup after we made the deal.

The engine is basically the same as the one that came out of my car, except that it was fuel injected (I didn’t need that) and a 4.2 liter. The water pump and belting is a little different, and (as the picture shows) the XJ6 has a fan attached via the water pump. It also has an electronic ignition, which I will keep. The block itself is configured a bit differently for the XJ6, since it uses the E-type engine mount points for the power steering pump (and something else on the other side). The XJ6 engine mounts are set a little further back. The nice thing is that you can still use the E-type mounts in their appropriate places — just remove te brackets for the other stuff and stick in the engine mount brackets. The cylinder head has a couple of extra holes for coolant, and some subtle changes that are less of a bother, probably. (See below for information about the head.) David provided the XJ6 exhaust manifolds that I’m going to try to use. The originals I have are fine, but I like the XJ manifolds, and I’d like to keep the heat shield in place, since damage to the bonnet paint over the manifolds has been reported.

David has about a dozen XJ6’s in his collection of parts cars, ranging from series one through three. He has a series one that looks like a good candidate for restoration — a right-hand drive model with some interesting details. It was damaged a little on an outer sill, but that was a pretty easy repair, I thought. He’s working on another XJ that’s perched on the ramp that you can barely see in the background of the picture. Instead of an XJ6, this one is an XJ12, with a front end full of metal. I don’t know what his ultimate plans are for the car, but it’s a good project. I think it would take me a long time to take on a V-12, though it would be fulfilling to complete … until you have to pay for the fuel, of course.

I walked his grounds, visited his horses, met his wife and 22-month old daughter. I determined he was a good man to buy an engine from. I certainly know where I’ll be able to find E-Type parts that might be interchangeable with the XJ series. And, seeing those old XJs made  me wonder if I should try my hand at one of those eventually. I have an XJ8 (I think they call it an X308 model, or the like) now, and it’s a wonderful car. The earlier version XJ6 series has the same glove-like, natural quality. The interiors of David’s cars, though most of them were worn out, still had that Jaguar feel. In my opinion, the XJ6, series one through three, were nice cars, but the following boxy ugly version of the late 80s seems to have lost its way. Jaguar found the path again with the XJ model that currently is offered, I think.

me wonder if I should try my hand at one of those eventually. I have an XJ8 (I think they call it an X308 model, or the like) now, and it’s a wonderful car. The earlier version XJ6 series has the same glove-like, natural quality. The interiors of David’s cars, though most of them were worn out, still had that Jaguar feel. In my opinion, the XJ6, series one through three, were nice cars, but the following boxy ugly version of the late 80s seems to have lost its way. Jaguar found the path again with the XJ model that currently is offered, I think.

He walked me to pay homage to the donor car, which sat at the end of a row, sans rear suspension, front end akimbo, left front panel gone, lights poked out — all probably mounted on other rides somewhere.

David is a square dealer, and he offered me the history he had of the engine and its donor car, telling me what did and did not work. He lives near Rockwell, North Carolina, which is not too far from Charlotte. He’s probably most available by email: david@everydayxj.com. I’m adding him to my list of suppliers, since there do seem to be useful overlaps of parts between the E-type and the good old XJs. [Added 20 January 2008: David has a website now: http://everydayxj.com.]

It’s been striking to see how much the early E-type engines were ornamented. The engine block from the XJ6, cast and fitted during the dread British Leyland years, was crudely sprayed a faded blue. The cylinder head on our old cars were painted gold and the area covering the timing chains was smoothed and polished, or at least brushed. The XJ6 head was barely extracted from the sand after it was cast and then  quickly gone over with a grinder to remove casting seeps. and seams. No cosmetics in the late 70s, I’m afraid.

quickly gone over with a grinder to remove casting seeps. and seams. No cosmetics in the late 70s, I’m afraid.

The “bottle jack” method of cylinder head removal

In short, the cylinder head was a bugger to get off. The head bolts had corroded, except for the pairs on each end. I guess this is quite common. I first thought that the head gasket was giving us the trouble, but quick taps of the bolts (with head nuts fittted, of course) quickly told us which ones were locked tight. They were the ones that didn’t budge or rattle in the least. Aaron squirted bolt loosener (PB “Blaster”), and that seemed to help a bit, and we made tiny headway to free the corroded bolts.

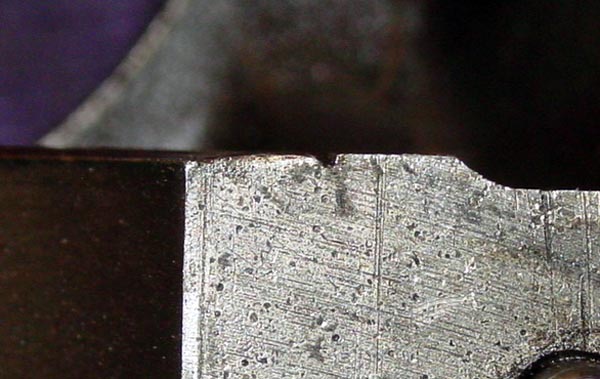

But a quick search on Jag Lovers brought up references to a “bottle jack” method that appeared to be quite effective. I have to admit that I was a little baffled, but at least I had a couple of hydraulic jacks. They have done various and good service on everything from cars to ninety-year-old floor spans. Why not on a cylinder head, too? When I was sitting at the computer, I had no idea where the things would go, but with jacks in hand and kneeling next to the engine, it was apparent.

The underside of the head juts some way out from the top of the block, and the block itself has a shelf-like flare near the bottom. The jack sits between these points. The picture tells the story, at least in part.

I had intended on detailing the differences between the 1963 and 1979 cylinder heads in this entry, but I think I’ll delay that a bit, since we hurried the head to the machinists. When it comes back all fit and shiny, it’ll be a better example to look at in any case. I hope that the next entries might help some other restorer do a similar transplant.

When my dad was here, we inspected the tappets that accept pressure from the cams. One of these

When my dad was here, we inspected the tappets that accept pressure from the cams. One of these  appears to have been damaged either by dirt or by corrosion. The surface of the plate where the cam touches has been pitted. This will probably have to be replaced, since a roughened surface like that will certainly wear the cam and also be significantly weakened itself. The other tappets show almost no wear at all. My dad says that the cams bear the most pressure of any parts in an engine. They look to me to be models of precision and efficiency.

appears to have been damaged either by dirt or by corrosion. The surface of the plate where the cam touches has been pitted. This will probably have to be replaced, since a roughened surface like that will certainly wear the cam and also be significantly weakened itself. The other tappets show almost no wear at all. My dad says that the cams bear the most pressure of any parts in an engine. They look to me to be models of precision and efficiency. Caswell Plating and do the front suspension mounting brackets. The brackets fit into the subframe and really need to be installed at the time when the subframe is fitted. The pieces have surface area below the 16-square-inch per ampere of current that nickel requires. I was able to cobble together DC power sources to make about an amp, so 16-18 square inches was about the limit. Plating nickel is indeed easier than plating zinc. The electrical charge doesn’t have to be quite as precise, I think, for nickel. And, perhaps, experience counts a bit in plating. I was very pleased with the results.

Caswell Plating and do the front suspension mounting brackets. The brackets fit into the subframe and really need to be installed at the time when the subframe is fitted. The pieces have surface area below the 16-square-inch per ampere of current that nickel requires. I was able to cobble together DC power sources to make about an amp, so 16-18 square inches was about the limit. Plating nickel is indeed easier than plating zinc. The electrical charge doesn’t have to be quite as precise, I think, for nickel. And, perhaps, experience counts a bit in plating. I was very pleased with the results.

to the frame with three bolts that go into a fitting attached to the frame, sometimes slightly spaced with shims. These three-bolt brackets won’t lie flat on the surface of the wood, so I made a slight indent with the drill bit so that the piece would lie flush to the wood at the point where the bush was inserted.

to the frame with three bolts that go into a fitting attached to the frame, sometimes slightly spaced with shims. These three-bolt brackets won’t lie flat on the surface of the wood, so I made a slight indent with the drill bit so that the piece would lie flush to the wood at the point where the bush was inserted.

through Florida to see relatives and participate in a travel exchange with people in Sarasota. I was a little worried about suggesting that we take on a project with the old car, since I didn’t want to impose my restoration work on an unwilling participant, but it actually turned out that Dad wanted to do exactly that.

through Florida to see relatives and participate in a travel exchange with people in Sarasota. I was a little worried about suggesting that we take on a project with the old car, since I didn’t want to impose my restoration work on an unwilling participant, but it actually turned out that Dad wanted to do exactly that. bonnet fit against the lower sections of the bulkhead and the upper sections. Things were slightly wider at the upper part than at the lower, meaning that we could raise the bonnet to even things out.

bonnet fit against the lower sections of the bulkhead and the upper sections. Things were slightly wider at the upper part than at the lower, meaning that we could raise the bonnet to even things out.

of them all together, so that we can take a closer look at the crankshaft. I spoke with my dad on the telephone over the weekend about the crankshaft. He tried replenishing bearings on an old engine once before, and they gave way shortly afterward. If the crankshaft is not true — if it has miniscule flatnesses especially — the crankshaft eats up the new bearings in short order. So, I’m going to look around for a machine shop that can check the crankshaft in all of its places and, if need be, turn and otherwise repair it.

of them all together, so that we can take a closer look at the crankshaft. I spoke with my dad on the telephone over the weekend about the crankshaft. He tried replenishing bearings on an old engine once before, and they gave way shortly afterward. If the crankshaft is not true — if it has miniscule flatnesses especially — the crankshaft eats up the new bearings in short order. So, I’m going to look around for a machine shop that can check the crankshaft in all of its places and, if need be, turn and otherwise repair it.

and was delighted that we could walk away with ours for under $40 USD. We hadn’t really explored the engine — like the removal of the oil pan to inspect the crankcase area — and the engine stand made this much more possible. Most engine stands connect to the engine by the bolts used to attach the bell housing at the rear end of the engine block. (I’m not sure exactly how new-fangled sideways engines are attached to their engine mounts. I assume that there is a wholly different breed of engine stands for such engines.)

and was delighted that we could walk away with ours for under $40 USD. We hadn’t really explored the engine — like the removal of the oil pan to inspect the crankcase area — and the engine stand made this much more possible. Most engine stands connect to the engine by the bolts used to attach the bell housing at the rear end of the engine block. (I’m not sure exactly how new-fangled sideways engines are attached to their engine mounts. I assume that there is a wholly different breed of engine stands for such engines.) At this point we have not investigated the damage that may (or, we hope, may have not) been caused by the lack of thrust washers. They were a bit of a mystery at first, since they obviously were not crankshaft bearings and they gave the impression of being halves of a single large washer that was split. The thrust washers fit on both sides of the middle crankshaft support. I think they stabilize the crankshaft from forward and backward movement, though I don’t know how critical they are, since it would seem to me that most of the strain on the crankshaft would be vertical and horizontal — coming from the up and down motion of the pistons. A cursory look at the middle support and the surrounding fittings revealed no apparent damage. We’ll need to see about the wear in this area, just to see if the section is so large that the thrust washers won’t fit snugly.

At this point we have not investigated the damage that may (or, we hope, may have not) been caused by the lack of thrust washers. They were a bit of a mystery at first, since they obviously were not crankshaft bearings and they gave the impression of being halves of a single large washer that was split. The thrust washers fit on both sides of the middle crankshaft support. I think they stabilize the crankshaft from forward and backward movement, though I don’t know how critical they are, since it would seem to me that most of the strain on the crankshaft would be vertical and horizontal — coming from the up and down motion of the pistons. A cursory look at the middle support and the surrounding fittings revealed no apparent damage. We’ll need to see about the wear in this area, just to see if the section is so large that the thrust washers won’t fit snugly.

I suppose this wasn’t really necessary at this point, but it can do nothing but good to remove some of the collected grit from the cylinders and pistons. This cleaning had the benefit of allowing us to see markings on the pistons that show that these pistons are oversized by 0.030 of an inch. That is the largest size that Jaguar recommends before resleeving the cylinders and resizing the pistons to their initial measurements. The markings also confirm absolutely that the engine has been overhauled (not an unusual thing, of course — it would be far more unusual to find an engine of this vintage that had not been overhauled).

I suppose this wasn’t really necessary at this point, but it can do nothing but good to remove some of the collected grit from the cylinders and pistons. This cleaning had the benefit of allowing us to see markings on the pistons that show that these pistons are oversized by 0.030 of an inch. That is the largest size that Jaguar recommends before resleeving the cylinders and resizing the pistons to their initial measurements. The markings also confirm absolutely that the engine has been overhauled (not an unusual thing, of course — it would be far more unusual to find an engine of this vintage that had not been overhauled). a time, to replace the rings and bearings. Then after one is back in place, we’ll remove the next one, and so on. This, of course depends on whether we’ll need to remove the crankshaft to do whatever needs to be done about the thrust washers. At this point, however, I’m thinking that the issue with the thrust washers was a matter of incorrect installation or perhaps a misfit of part. As a matter of fact, it’s not clear to me that the thrust washers were in fact replaced at the last overhaul. The ones that were mangled may indeed have been the originals. I don’t know yet.

a time, to replace the rings and bearings. Then after one is back in place, we’ll remove the next one, and so on. This, of course depends on whether we’ll need to remove the crankshaft to do whatever needs to be done about the thrust washers. At this point, however, I’m thinking that the issue with the thrust washers was a matter of incorrect installation or perhaps a misfit of part. As a matter of fact, it’s not clear to me that the thrust washers were in fact replaced at the last overhaul. The ones that were mangled may indeed have been the originals. I don’t know yet.